INTRODUCTION:

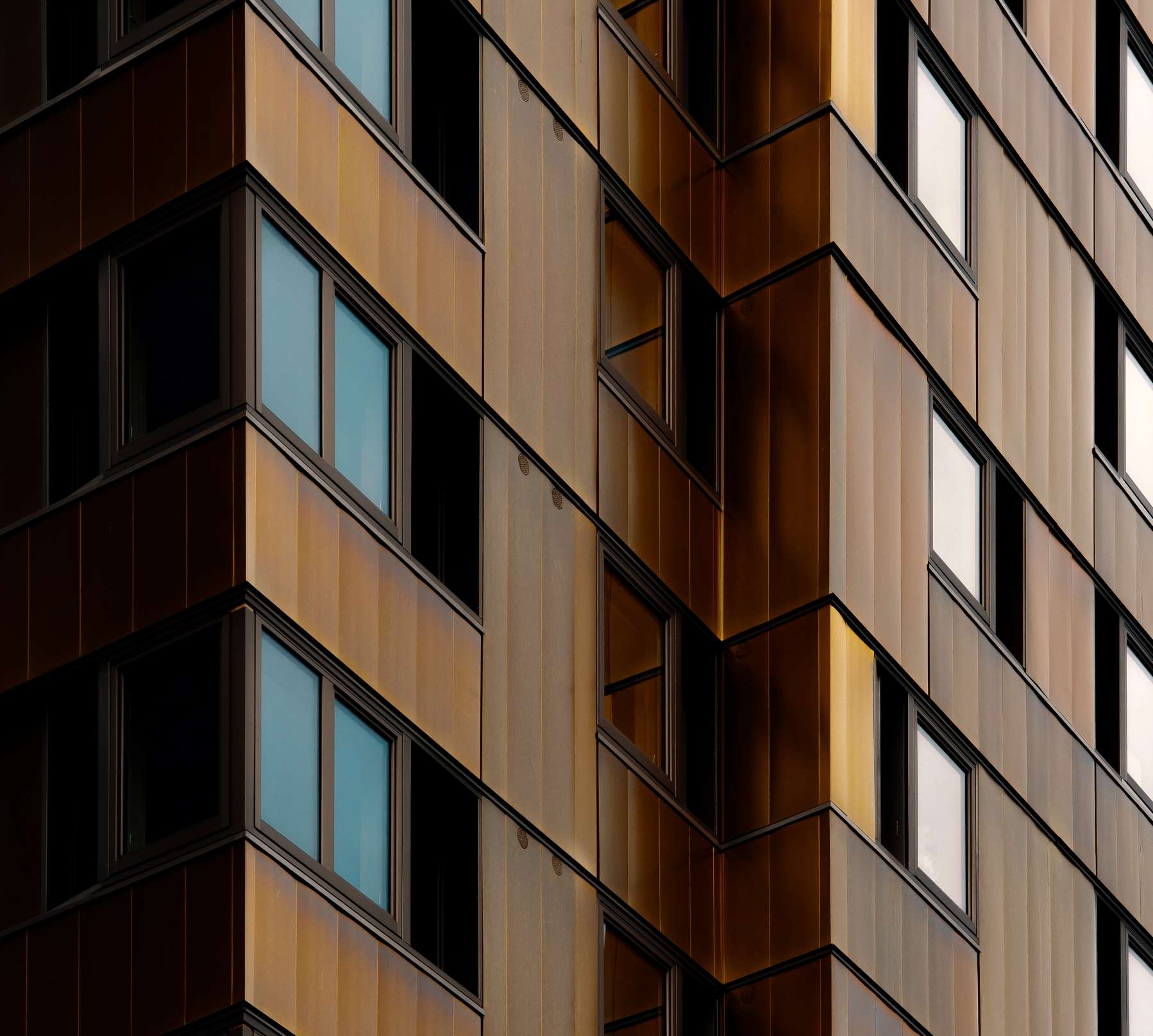

Panelling and glazing represents new trends of beautifying exteriors of the buildings. It also helps in providing safety, adding illumination and controlling sound. These are perfect replacement for conventional cladding materials such as marble, granite, decorative artificial stones, textures etc. It increases the expected value of commercial or residential projects.

ALUMINUM COMPOSITE PANELS

An aluminum composite panel is made by sandwiching two skins of aluminum sheets with a nontoxic polyethylene core having fluorocarbon coating. This coating is applied on the top, ensuring superior corrosion resistance and weatherability.

This material has following properties :-

- Excellent flatness

- Light weight

- High strength

- Durable

- Corrosion resistance

- Sound isolation

- Thermal isolation

- Impact resistance

- Easy for installation

- Quick installation

- Vivid colours

- Maintenance free

- Easily available

- Easily mouldable

Alongwith the versatile properties mentioned above, this material is available in attractive colours, finishes and thicknesses, therefore it is set to become a leading choice for building exteriors, foyers, ceilings, elevators, office interiors, shop fronts, signboard etc.

WORK PROCEDURE

- Erect a firm and workable M.S. scaffolding to facilitate the panel fixing work.

- Mark the grid lines as per decided panel sizes.

- Fix M.S. angles with holes in line, level and plumb, to serve as the basic frame.

- Fix aluminum composite panel with screws on grids as per designed grooves.

- Fill the sealant in grooves, taking utmost care.

- Remove the protection film and clean the panel with soft cloth.

0 Comments